The MDS (Measurement Data Service) software component is a Embedded Software Library, that is used in multiprocessor systems for efficient, synchronous and time-stamped derivation of data. Here, the generation of the appropriate XML signal description file takes place via a supplied symbol parser for C. This ensures a later reusability of the data streams in highly accurate simulation or Hardware-in-the-Loop systems. By integrating with a wide variety of operating systems, the software developed for the ADAS/AD domain allows data to be sent highly efficiently from an ECU to a recorder unit.

Why choose MDS?

Key Features

MDS specializes in efficient data derivation within multiprocessor systems, providing synchronous and time-stamped data collection. This is critical for ensuring data accuracy and consistency in complex automotive systems. The software's ability to generate XML signal description files using a C-based symbol parser enhances the reusability of data streams in simulations and hardware-in-the-loop systems, making it a versatile tool for various stages of automotive software development.

Designed for the ADAS/AD domain, MDS integrates smoothly with a variety of operating systems and the classic AUTOSAR platform. This compatibility ensures that data from electronic control units (ECUs) can be sent efficiently to recorder units, facilitating seamless data flow in automotive systems. Additionally, the software's flexibility in connecting to high-speed interfaces such as PCIe and LVDS allows for the handling of high data rates, crucial for transmitting complex algorithms, BSW signals, trace, or clone information.

MDS is equipped with robust protection mechanisms and precise time stamps, providing maximum transparency for fault analyses, integration tests, and test drives. This feature is invaluable for identifying and addressing issues within automotive systems. Furthermore, as an integral part of the system for data recording, evaluation, and error analysis, MDS plays a crucial role in the resimulation processes for both hardware-in-the-loop (HiL) and software-in-the-loop (SiL), thereby enhancing the overall reliability and performance of automotive software systems.

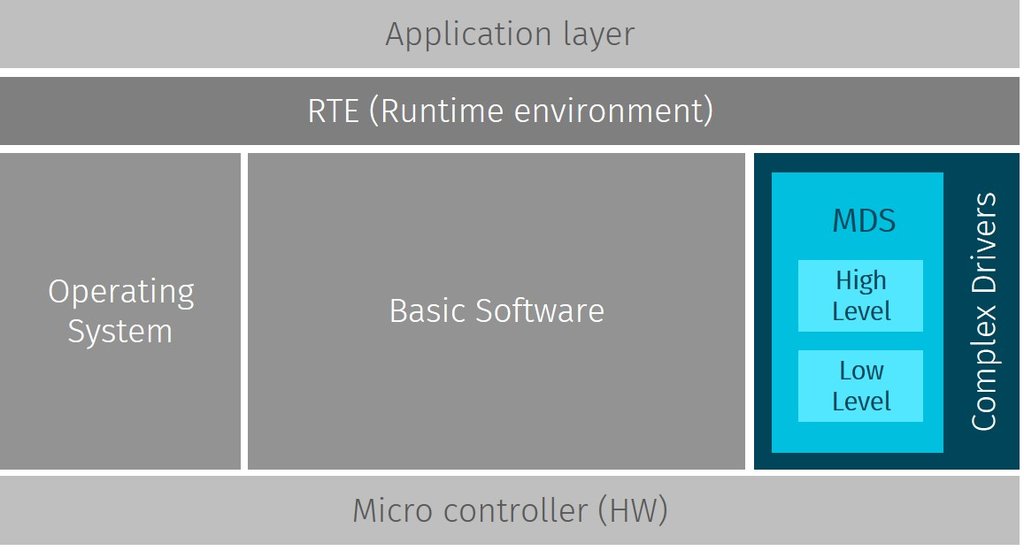

Integration of MDS into the classic platform of AUTOSAR

Autosar integration

Autosar, QNX & Linux compatibility

Operating systems in comparison

Establishing common standards in ECU development: that is the goal of the AUTOSAR (Automotive Open System Architecture) development partnership.

We are proud to have been part of this initiative since 2018. As an AUTOSAR Associate Partner, we use the latest standards. The insights gained from this are continuously incorporated into current and future customer projects as well as our own solutions.